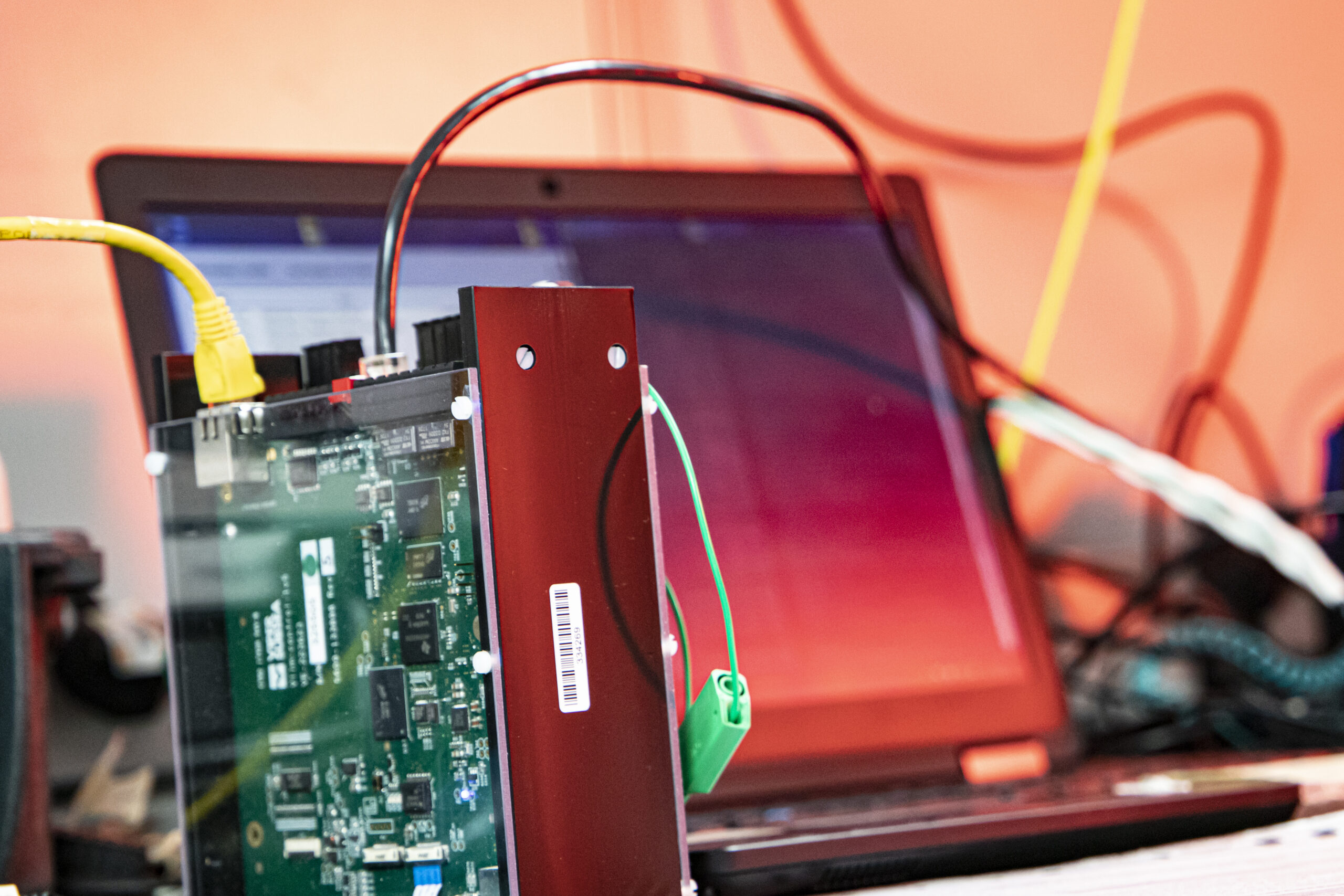

Functional Testing

Quality and service at the

heart of our business

With quality and service at the heart of the business, the company deploys sophisticated test resources to fully verify assemblies.

Test drives quality so Active-PCB tests to its customers’ exact specifications and beyond using a combination of flying probe, in-circuit, functional and boundary scan systems, backed up by environmental tests to guarantee dependability in the field – a critical aspect for customers in the oil & gas industry, among others.

Flying Probe Test.

- Shorts Testing utilising both adjacent pin & NZT techniques

- Device and Pin “opens”

- Full analogue parametric testing

- Vectorless IC open pin testing

- Digital testing via probes and fixturing/cables

- Optical Test

- Powered Test

- Device Programming

Burn-in and Heat-soaking

Active-PCB offers burn-in and heat-soaking of assembled products to detect particular components that would fail during the initial, high-failure rate stage of a products life.

In Circuit Functional Test

A comprehensive selection of test equipment complements any bespoke items required to test your products so that all of your functional test needs can be catered for.

Boundary Scan

JTAG Technologies is used to carry out boundary scans of products. This is a method of testing wire lines on printed circuit boards, and is widely used by many companies across the world as a means of quality testing.

Contact us so we can better understand you

Every customer has their own needs, their own standards to adhere to and their own projects with unique specifications. Active-PCB is a partner in finding the right solution first time. Ask us a question, request information or enquire whichever way best suits you.