MRP system

MRP system

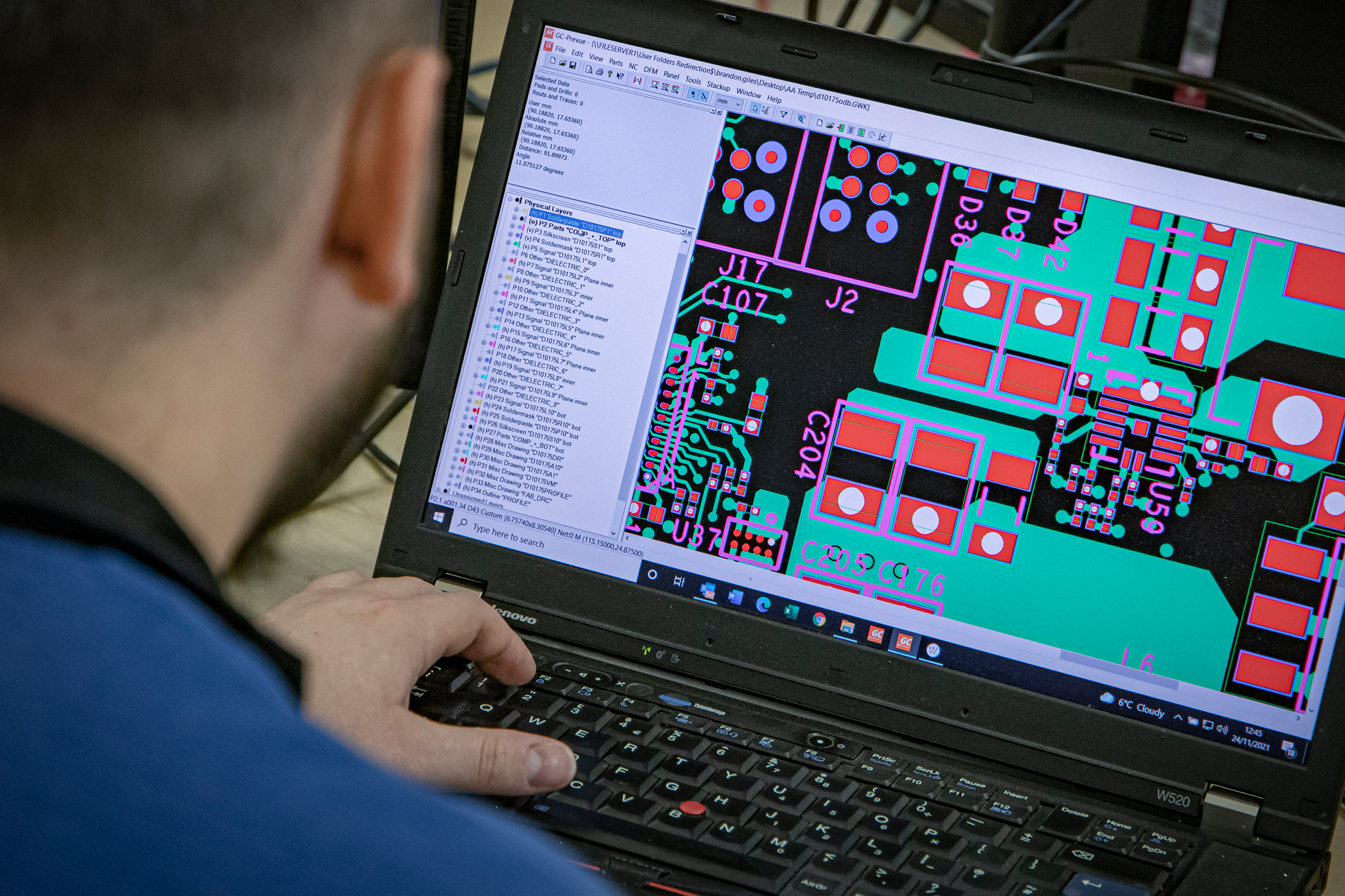

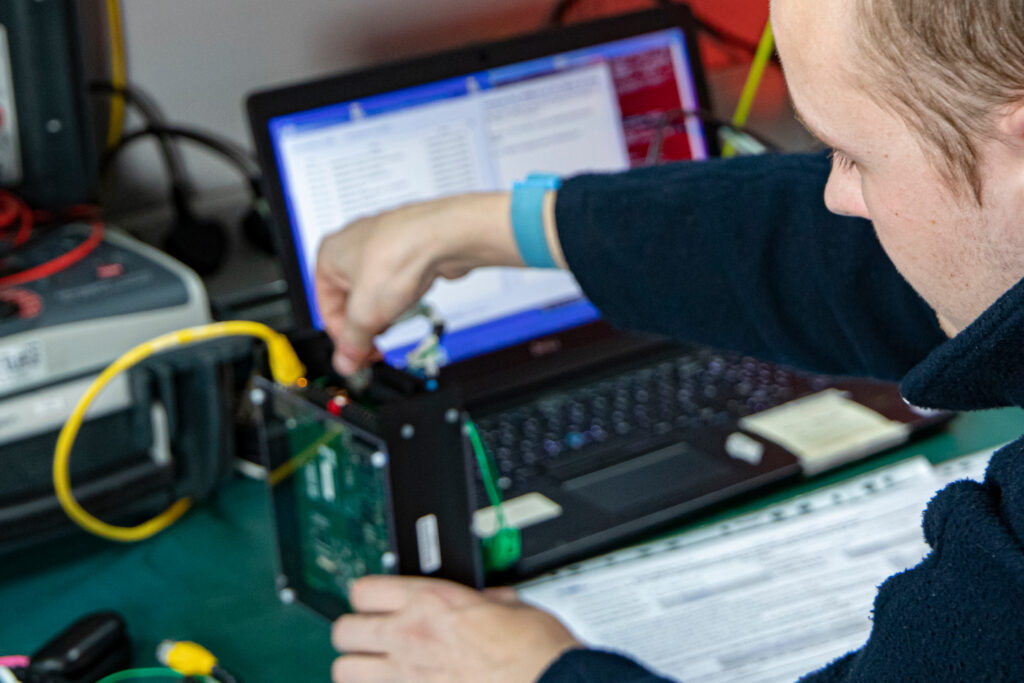

Active-PCB’s Material Requirements Planning (MRP) system is used for planning and decision making when manufacturing a product.

It helps by monitoring current levels of supply against production capacity, whilst also providing forecasts based on potential production timelines.

The system consists of three primary steps:

Material Inventory

Noting what additional materials are required

Scheduling the purchase of new materials or production

The MRP system helps the company to minimise the amount of inventory that isn’t required, allowing Active-PCB to use space more wisely and not be overstocked. It is also an incredibly useful tool as it tracks every one of the orders that go through, whether it be for purchasing or for production purposes.

With less time wasted, a closer eye on production processes, and more space for Active-PCB to utilise, the MRP system is a hugely vital tool to not just the customer, but also the company’s resources.

Contact us so we can better understand you

Every customer has their own needs, their own standards to adhere to and their own projects with unique specifications. Active-PCB is a partner in finding the right solution first time. Ask us a question, request information or enquire whichever way best suits you.