Testing and Inspection.

Overview

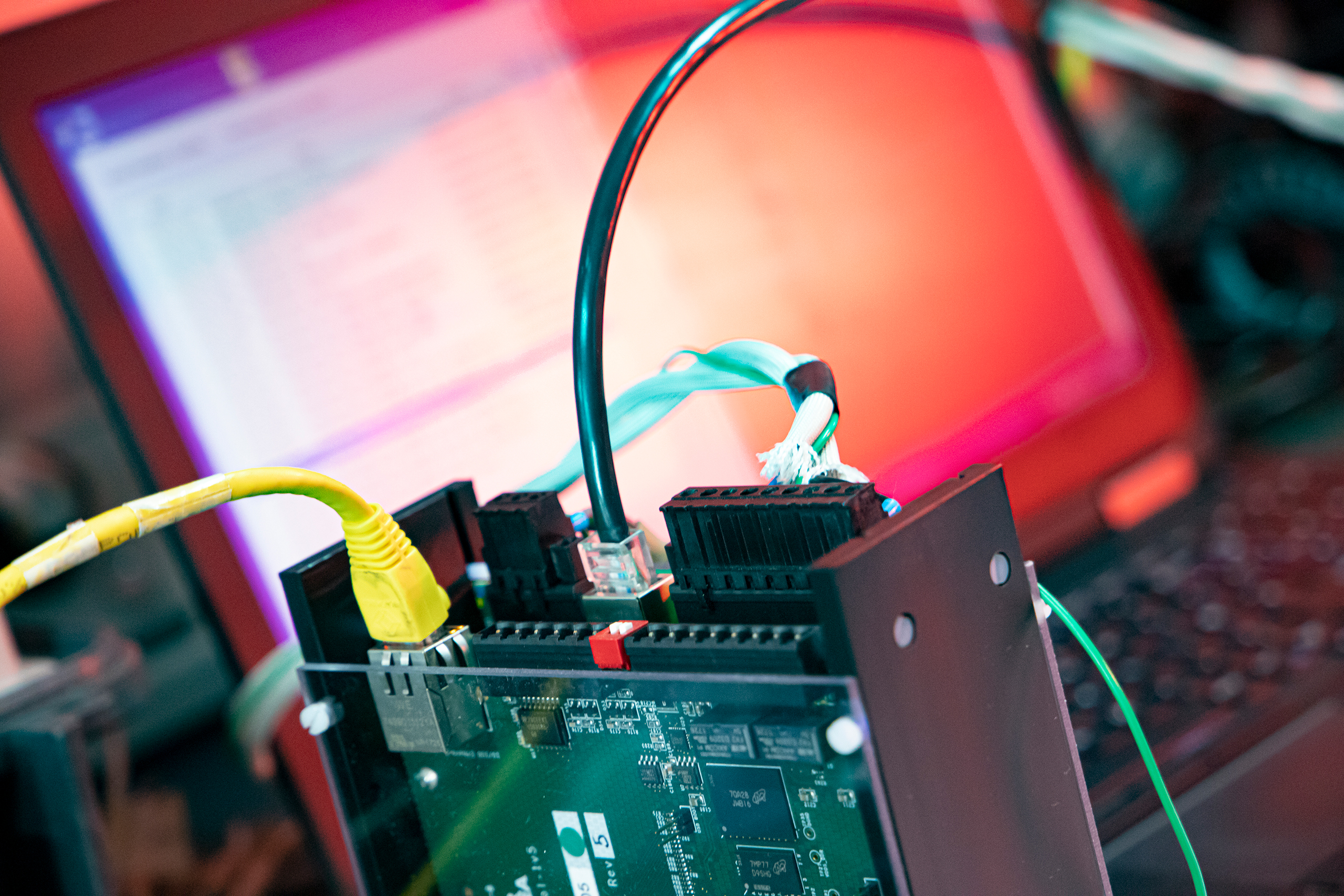

It is always important to undertake testing & inspection before products are classed as completed and ready to go to the customer.

Through several processes and procedures, test equipment is used to certify that Active-PCB’s output is to the highest of standards. If the customer requires, testing is done to confirm that the board works functionally.

Inspection is undertaken to confirm that all the parts are fitted correctly and within the specified tolerances, making sure that customer requirements are met. This is done by using a variety of different, highly technical equipment that searches for even the smallest of defects, as well as the skills and experience of Active-PCB quality inspectors.