When deadlines are tight and innovation cycles are short, rapid PCB prototyping becomes a critical part of product development. But as engineers and designers push for faster turnaround times, a recurring concern arises: Does increasing the speed of PCB prototyping mean compromising on the quality?

The answer is… possibly. However in this article, we’ll explore how Active-PCB Solutions ensures fast delivery of prototype PCBs without sacrificing quality and precision.

What is Rapid PCB Prototyping?

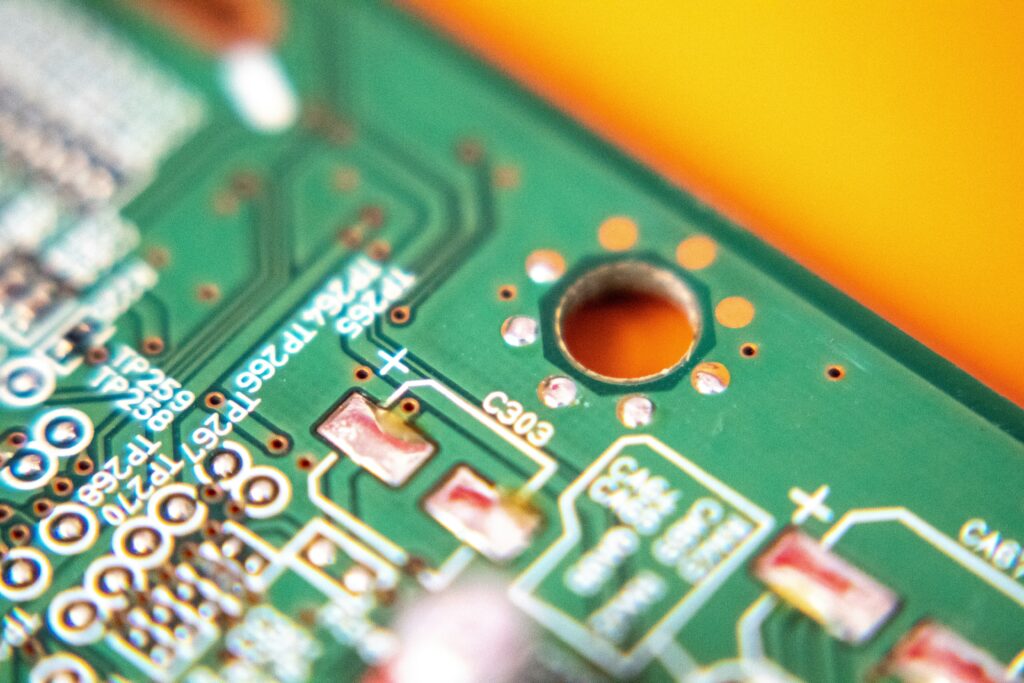

Rapid PCB prototyping is the process of quickly manufacturing a small batch of printed circuit boards for testing and evaluation purposes. These prototypes are essential for verifying design, functionality, and manufacturability before moving into full-scale production.

Speed vs. Quality in PCB Prototyping: What’s the Trade-Off?

The Advantages of Speed

- Faster product development cycles: Rapid prototyping means products can be brought to the market sooner.

- Early error detection: Allows for testing and early fixing of design flaws.

- Agile iteration: It is possible to implement changes quickly across multiple prototype versions.

Potential Risks of Rapid Turn Prototyping

- Material limitations: Some quick-turn services may use lower-grade materials.

- Reduced testing: Less time between prototype batches may mean fewer QA checks unless processes are streamlined.

- Supplier shortcuts: Not all manufacturers uphold strict quality standards when under time pressure; human error is likely to be increased when pressure is high.

How We Maintain Quality During Rapid Prototyping

At Active-PCB Solutions, we believe that speed and quality can coexist. Here’s how:

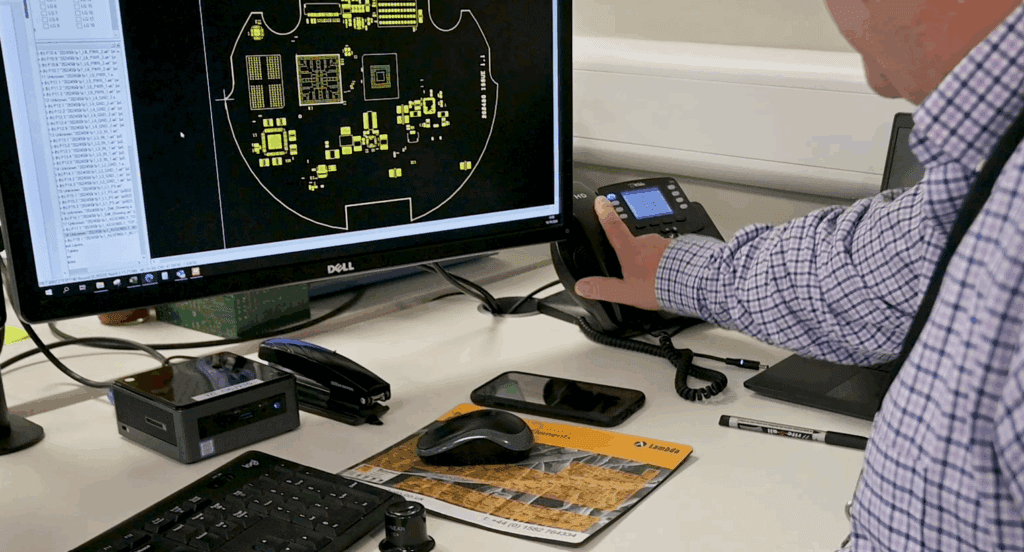

1. Design for Manufacturability (DFM) Review

Every rapid prototype order includes a rigorous DFM review conducted by trained and experienced engineers. This allows us to catch common design issues before fabrication begins.

2. High-Precision Equipment

We use automated SMT lines, AOI (automated optical inspection), and X-ray testing to maintain quality even on tight schedules.

3. Material Consistency

Unlike some quick-turn shops, we never compromise on materials, even on urgent jobs.

4. Dedicated Rapid Prototyping Line

We are able to operate a dedicated line specifically for prototypes, ensuring that urgent orders don’t bottleneck with larger production runs.

When Should You Use Rapid PCB Prototyping?

Rapid PCB prototyping is ideal for:

- Proof-of-concept boards

- Functional testing

- Investor or stakeholder demos

- Pre-certification testing

For mission-critical applications (medical, aerospace), a hybrid approach – fast prototyping followed by in-depth validation – is often best.

Why Should you Choose Active-PCB Solutions for Rapid PCB Prototyping?

- Turnarounds in as little as 24–48 hours

- UK-based engineering support

- ISO 9001-certified processes

- No compromise on component sourcing or inspection

Whether you’re refining a new IoT device or prepping for production, Active-PCB helps you move fast and smart.

Ready to Prototype Fast?

If you are looking for rapid PCB prototyping, speak to our engineers about your design needs. We’ll help you get your prototype built, without cutting corners.