When sourcing a PCB assembly partner, cost often becomes the primary focus. But many OEMs overlook the hidden costs of poor PCB assembly; issues that quietly erode profit margins, delay product launches, and damage long-term brand reputation.

Here are the top five hidden costs that can result from poor or low-cost PCB assembly, and how to avoid them by choosing a quality-focused manufacturing partner – like Active-PCB Solutions.

1. Product Failures in the Field

The cost: Warranty claims, customer dissatisfaction, and damage to your brand reputation.

Failures caused by poor solder joints, incorrect component placement, or substandard materials are not always immediately obvious. Instead, they emerge weeks or even months after the product has been launched to the market, damaging customer trust and forcing you to absorb costly repairs or replacements.

How to avoid it:

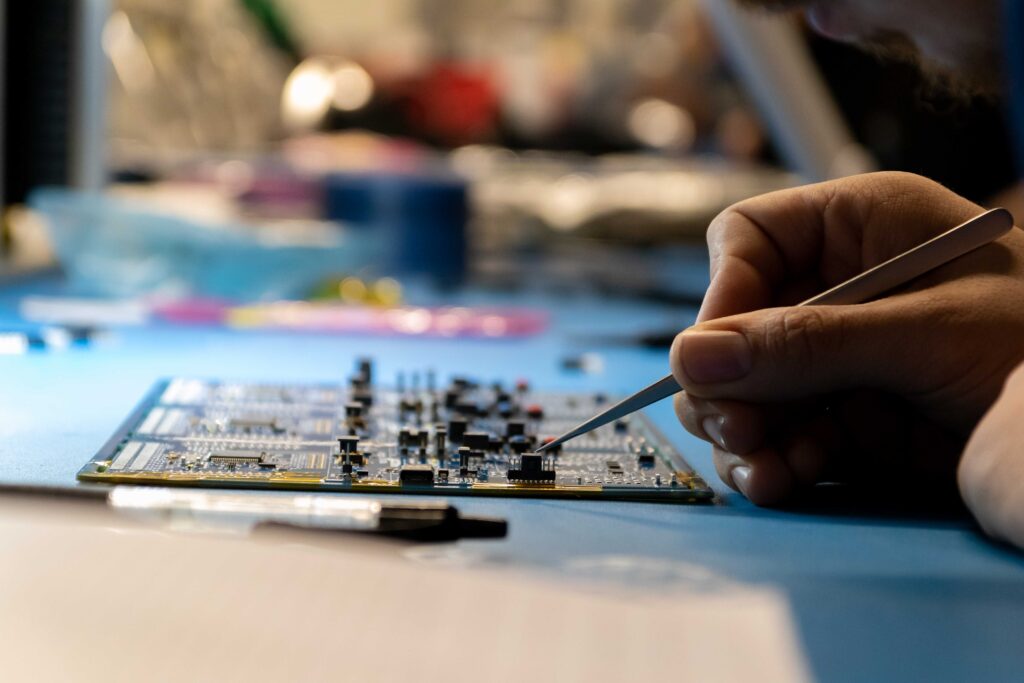

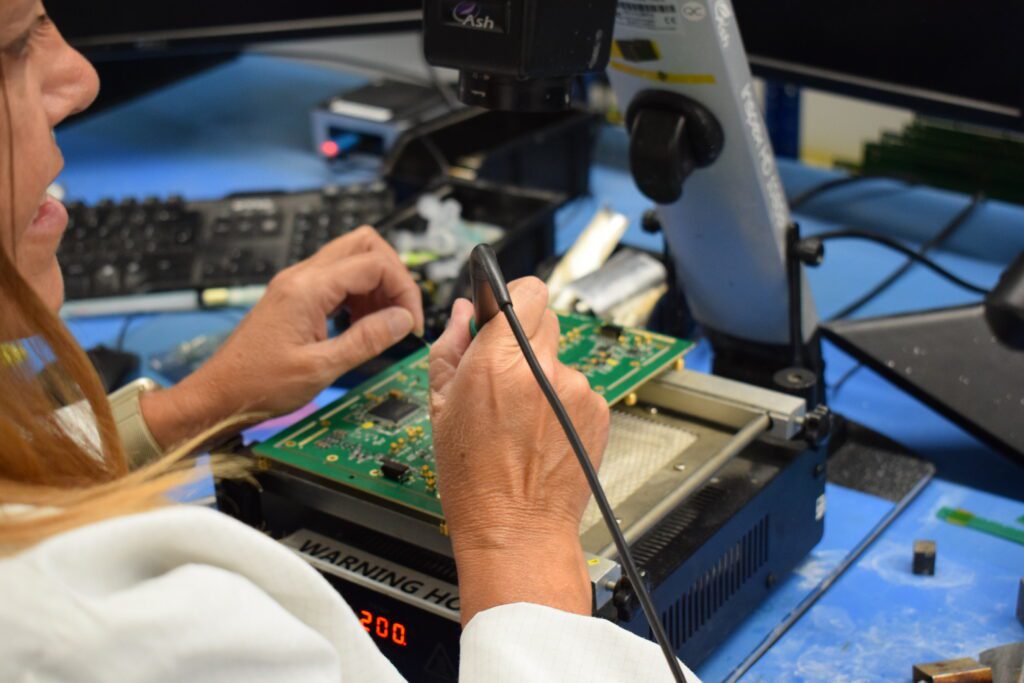

Choose a PCBA partner that prioritises in-process quality control. At Active-PCB Solutions, we use a combination of automated optical inspection (AOI), X-ray inspection, and functional testing to catch issues early and ensure that the electronics leaving our factory floor work as expected, every time.

2. Costly Redesigns and Rework

The cost: Engineering time, added materials, missed deadlines.

Redesigns often stem from a lack of design-for-manufacturability (DFM) input, poor assembly accuracy, or incomplete documentation. Once errors are discovered post-assembly, you’re forced to troubleshoot, revise, and rerun – and all can come with significant cost attached.

How to avoid it:

Look for a PCB assembly partner who offers DFM analysis and has experienced and knowledgable staff who collaborate closely with your engineering team early in the design phase. Our technical team at Active-PCB provides pre-build reviews to prevent costly rework and streamline production.

3. Delays in Time-to-Market

The cost: Lost revenue opportunities and competitive disadvantage.

One of the most overlooked hidden costs of PCB assembly is delay. Whether caused by poor planning, slow issue resolution, or low manufacturing capacity, delays can push product launches off schedule, resulting in missed opportunities or seasonal deadlines.

How to avoid it:

Partner with a manufacturer that’s structured for speed and scalability. Active-PCB is known for responsive project management and fast turnaround times even for complex, low-to-mid volume builds.

4. Compliance and Certification Risks

The cost: Regulatory failures, blocked market access, and reputational harm.

Non-compliance with industry standards like IPC-A-610 or ISO 9001 can result in failed audits, rejected shipments, and loss of access to regulated markets.

How to avoid it:

Work with an assembly house that meets and documents all relevant certifications. At Active-PCB Solutions, compliance is built into our quality system, with traceability and documentation provided for every build.

5. Long-Term Brand Damage

The cost: Customer churn and reduced market confidence.

While component failures and production errors are frustrating, the long-term consequence is often brand erosion. Customers don’t blame your supplier; they blame you – and once that trust is lost, even future products may struggle to gain traction.

How to avoid it:

Choose a trusted manufacturing partner that sees quality as a long-term investment, not a short-term checkbox. At Active-PCB, we protect your reputation with dependable, repeatable quality that reflects positively on your brand.

How to Avoid the Hidden Costs of PCB Assembly

Choosing the cheapest PCB assembly quote may seem smart in the short term, but the true costs often reveal themselves later.

From rework and delays to compliance failures and brand damage, the hidden costs of poor PCB assembly can be far more expensive than investing in a trusted manufacturing partner.

At Active-PCB Solutions, we help OEMs avoid these risks through:

- Early-stage technical input

- Robust inspection and testing processes

- Transparent communication and traceability

- Certified quality systems and regulatory compliance

Need a reliable partner for your next project?

Contact Active-PCB Solutions today and discover how we make the journey from concept to market smoother, faster, and more cost-effective.