When talking about electronics, the terms PCB and PCBA often come up, and they are sometimes used as if they mean the same thing. However a Printed Circuit Board (PCB) and a Printed Circuit Board Assembly (PCBA) are two distinct stages in the electronics manufacturing process.

For Original Equipment Manufacturers (OEMs), understanding the difference is more than just terminology; it affects sourcing decisions, cost structures, lead times, and ultimately the reliability of the final product.

What Is a PCB?

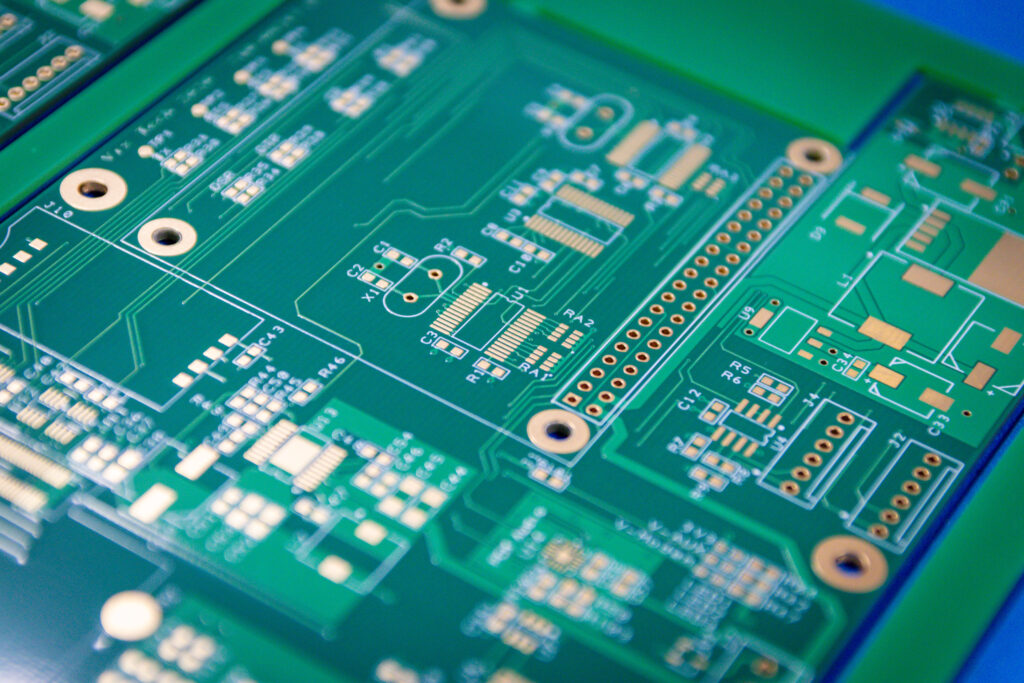

A Printed Circuit Board, or PCB, is the bare foundation of almost every electronic device. It consists of layers of insulating material, usually FR4 epoxy glass, laminated with copper traces that form the pathways for electrical signals. At this stage, the board is just a platform. It contains no electronic components and performs no function on its own.

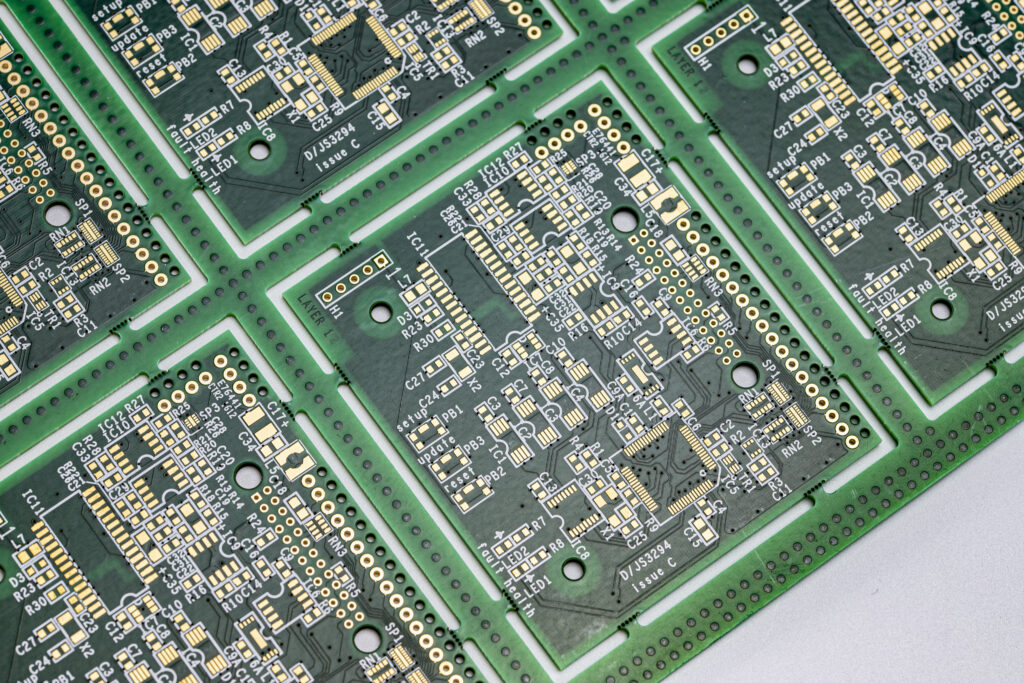

PCBs come in different types depending on complexity and application. Single-layer boards are used in simple consumer products, while multilayer boards with up to 20 or more layers are common in high-performance computing and aerospace. Flexible and rigid-flex PCBs allow design engineers to fit electronics into unusual form factors or tight spaces.

For OEMs, the PCB stage is primarily about design and fabrication. You’re dealing with layout, material choices, impedance control, and ensuring that the raw board meets your technical requirements.

What Is a PCBA?

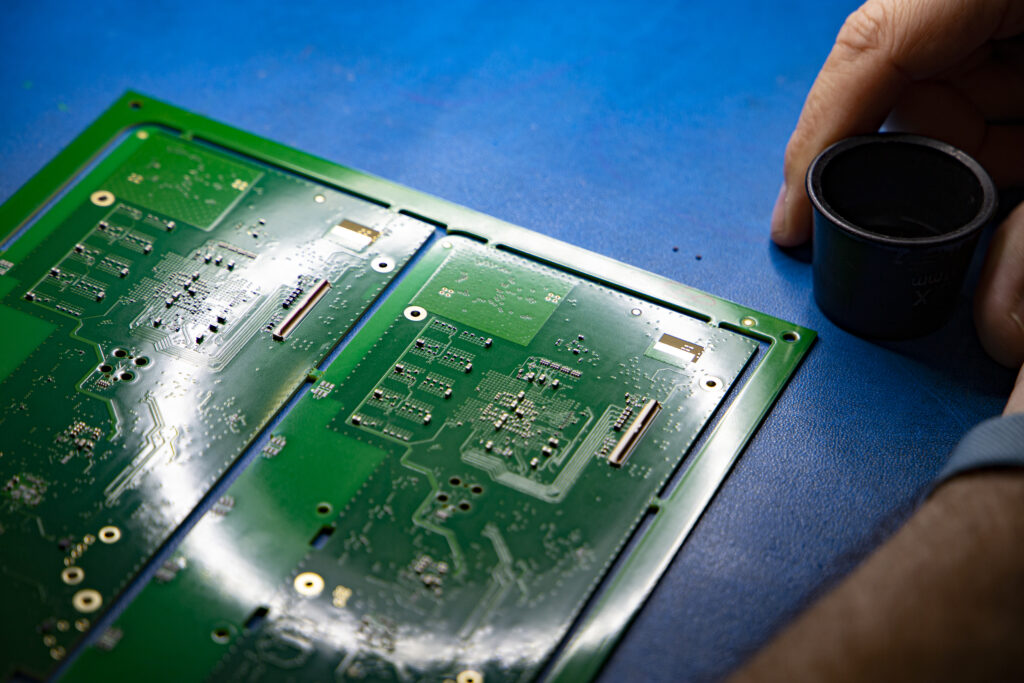

Once the bare board has been manufactured, it moves into the assembly stage, where it becomes a Printed Circuit Board Assembly (PCBA).

This is where the PCB is populated with electronic components; everything from resistors and capacitors to integrated circuits and connectors.

Modern PCBAs are built using two main methods: Surface Mount Technology (SMT), where components are placed directly onto the surface of the board, and Through-Hole Assembly, where component leads are inserted into drilled holes and soldered. Many boards use a mix of both.

After placement, the assemblies go through soldering, inspection, and testing.

Depending on the application, additional processes may be required. For aerospace, automotive, or medical electronics, conformal coating may be applied to protect the assembly from moisture, dust, and vibration. Functional testing ensures that the PCBA performs exactly as intended before it is integrated into a larger system.

At this stage, the board is no longer just a structure; it is a working circuit, the heart of a product.

The Key Differences Between PCB and PCBA

The most obvious difference is that a PCB is empty, while a PCBA is complete and functional. But there are deeper distinctions that matter for OEMs.

A PCB represents the design and fabrication phase. The focus is on materials, copper traces, and ensuring that the board is built to specification. A PCBA, by contrast, represents the full build. It includes component sourcing, placement, soldering, inspection, and often testing.

From a cost perspective, PCBs are relatively inexpensive. They are produced in volume by fabricators around the world. A PCBA, however, includes not just the board but also the components, labour, equipment time, and quality assurance. That means PCBAs account for the bulk of the value in electronics manufacturing.

Lead times also differ. Bare PCBs may be turned around quickly, especially for prototypes. PCBAs, on the other hand, are dependent on complexity and component availability. OEMs need to plan carefully and often benefit from working with a contract electronics manufacturer (CEM) like Active-PCB Solutions who can help manage the supply chain.

Why OEMs Need to Understand the Difference

For design teams, understanding where PCB ends and PCBA begins helps ensure better communication with suppliers. Misunderstandings can lead to delays, cost overruns, or boards that don’t meet application requirements.

For purchasing departments, separating PCB and PCBA costs allows for more accurate forecasting. It also highlights the importance of considering not just the cost of fabrication, but also the complexity of assembly and testing.

And for quality managers, recognising the distinction ensures that standards are applied correctly. A PCB might meet IPC-6012 for fabrication, while the PCBA must meet IPC-A-610 Class 2 or Class 3 depending on its end use.

The Role of a UK CEM Partner

This is where a UK-based CEM becomes invaluable. Instead of dealing separately with overseas board fabricators and multiple assembly houses, a CEM provides an integrated service. They can manage PCB sourcing, handle the PCBA build, carry out inspection and testing, and deliver a ready-to-use assembly.

For OEMs, working with a UK CEM brings additional advantages. Closer proximity means faster communication, easier collaboration, and shorter lead times compared to offshore assembly. Quality is easier to oversee, and traceability is built into the process.

There’s also the reassurance of local compliance with aerospace, medical, and defence standards; sectors where reliability is non-negotiable.

The difference between a PCB and a PCBA is straightforward

One – the PCB – is the foundation, the other – the PCBA – is the finished product. Recognising the distinction helps with design planning, cost management, and supplier selection. More importantly, it ensures that the electronics at the core of your products are reliable and built to the standards your industry demands.

Whether you’re sourcing bare boards, complete assemblies, or a full turnkey service, choosing the right UK-based CEM partner can make all the difference. Active-PCB can bring the expertise, quality assurance, and efficiency you need to bring innovative products to market with confidence.