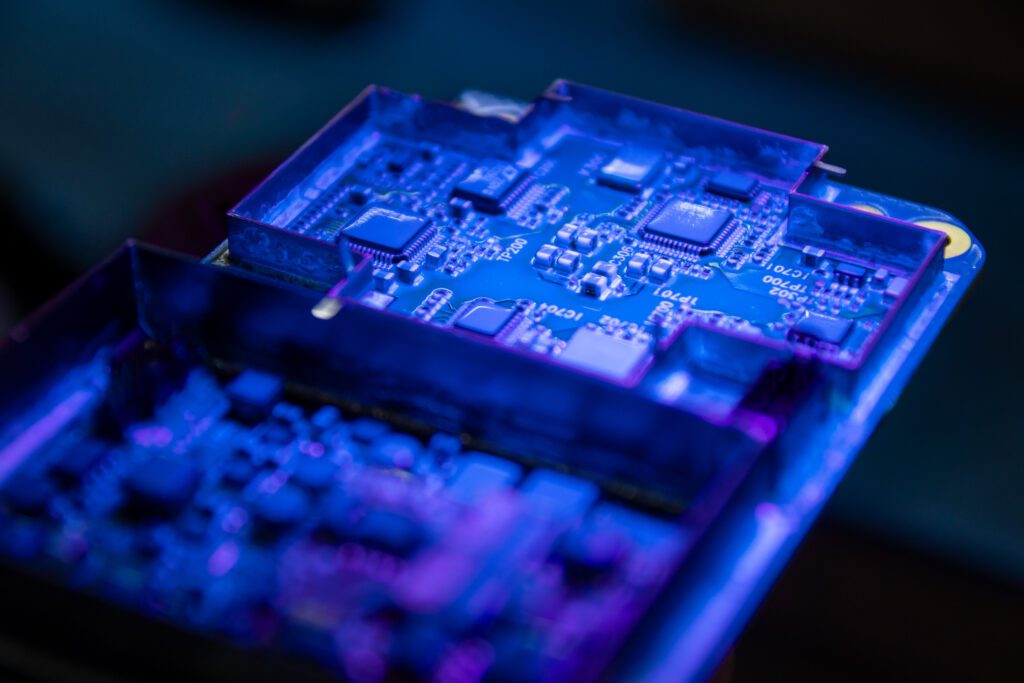

Conformal coating is one of those processes that looks straightforward on paper. The principle is simple: apply a thin, protective layer to a PCB assembly to guard against moisture, dust, and chemical exposure.

In practice, however, achieving consistent results can be a little more challenging. Even small deviations in process parameters can lead to visible defects or hidden defects which can affect the reliability of the PCB later on.

For OEMs, understanding these conformal coating defects and why they happen is essential when selecting a manufacturing partner or reviewing coating quality. For manufacturers, recognising them early and building robust processes is the key to avoiding costly rework.

Bubbles and Voids

One of the most frequently observed defects in conformal coating is the appearance of bubbles or voids trapped within the film. These occur when air becomes trapped during application, often due to incorrect spray pressure, poor material mixing, or outgassing from components during the curing stage.

Although bubbles may appear to be a cosmetic flaw, they compromise the uniformity of the protective barrier. A single void can provide a pathway for moisture, leading to corrosion or dendritic growth on sensitive circuit traces. In high-reliability industries, even a small defect of this type can render a board unacceptable. Careful control of application parameters and pre-bake processes for moisture-sensitive devices are critical to reducing this risk.

De-wetting and Pull-back

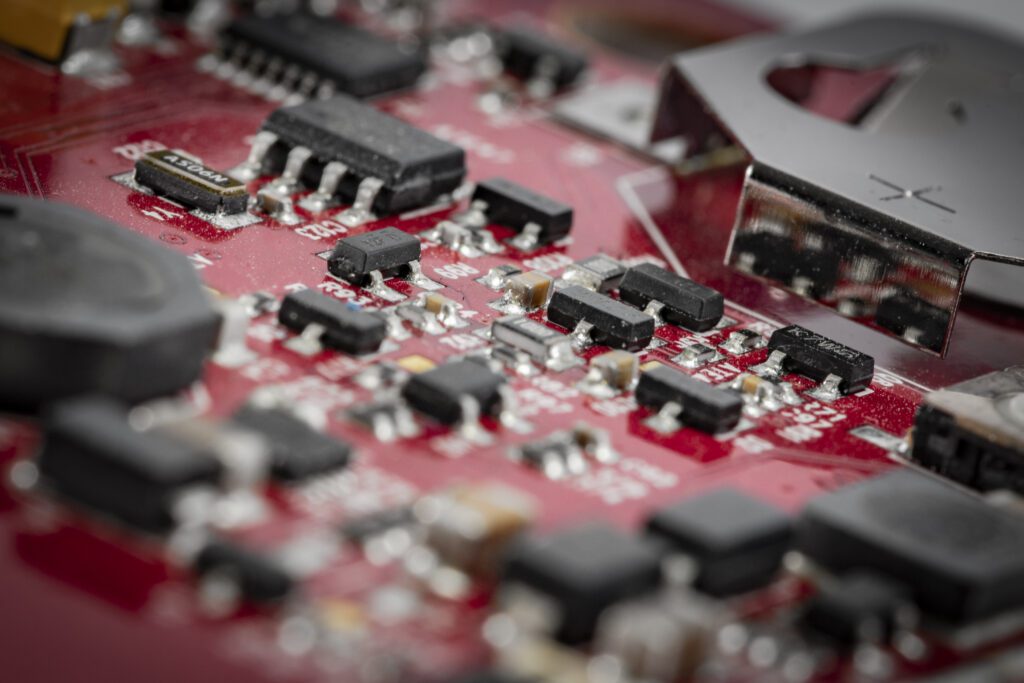

De-wetting occurs when the coating refuses to adhere evenly to the PCB surface, instead pulling back into beads or leaving exposed areas. This issue is almost always linked to surface contamination. Residues from solder flux, human fingerprints, or even trace amounts of silicone from previous processes can all prevent proper adhesion.

It can also be triggered by incorrect cleaning methods or the use of incompatible solvents. For this reason, surface preparation is one of the most important steps in the conformal coating process.

Robust cleaning protocols, testing, and surface energy checks ensure that the coating has the best chance of forming a continuous, reliable film.

Cracking

Cracks in a conformal coating usually appear after the assembly has been exposed to thermal cycling or mechanical stress. They often indicate that the coating material chosen is too rigid for the application environment, or that the film was applied too thickly.

Over-curing can also play a role, particularly with UV-cured materials that may become excessively brittle if exposed to high energy levels.

Once cracks form, the coating no longer offers protection and can even act as stress concentrators that accelerate component failure. Matching the coating chemistry to the expected service environment, and controlling film thickness, is the most effective way to prevent this conformal coating defect.

Orange Peel Effect

The orange peel effect describes an uneven, textured finish that looks similar to the skin of an orange. This surface irregularity is usually a sign of poor process control. Common causes include incorrect spray viscosity, poor atomisation during application, or applying the coating in layers that are too heavy.

While orange peel is sometimes dismissed as cosmetic, it can be an indicator of uneven coverage. Areas with thin coating may not provide adequate protection, while thicker areas may not cure properly. Maintaining consistent viscosity and ensuring the correct atomisation settings are vital for a smooth, uniform finish.

Bridging and Pooling

Excess coating can cause defects of its own. When too much material is applied, it can bridge across fine-pitch component leads or pool in recessed areas of the PCB. Bridging not only wastes material but can also cause functional issues, such as blocking connectors, coating switches, or preventing electrical test probes from making contact.

Pooling is equally problematic. Thick accumulations of coating may take significantly longer to cure, leading to soft or sticky areas on the board. Incomplete polymerisation can leave assemblies vulnerable to chemical attack or solvent absorption. Careful control of spray patterns, masking, and application volumes is essential to prevent these issues.

Delamination

Delamination occurs when the coating separates from the PCB surface, often lifting away in sheets or flakes. Like de-wetting, it can be caused by inadequate surface preparation, but it is also linked to thermal mismatches between the coating and the substrate.

In environments such as aerospace or automotive, where boards are exposed to wide temperature swings, delamination is a serious concern. Once separation begins, contaminants can migrate underneath the film, accelerating corrosion.

Selecting the correct material for the environment and qualifying the process thoroughly are critical steps in avoiding this high-risk defect.

Avoiding Conformal Coating Defects: Why Process Discipline Matters

The majority of conformal coating defects aren’t random, they’re process-driven.

By establishing a robust application method, controlling the parameters, and sticking to the process, conformal coating is reliable and repeatable.

Problems arise when small deviations creep in: a shift in spray pressure, inconsistent cleaning, or curing profiles that aren’t tightly controlled.

That’s why manufacturers who take coating seriously invest in:

- Thorough cleaning and inspection protocols before application.

- Tightly controlled application parameters (spray patterns, viscosity checks, masking methods).

- Regular process audits to ensure consistency.

- Skilled technicians and automated equipment where possible to minimise human variation.

Conformal coating is a simple by unforgiving process, and the execution demands precision.

For OEMs, awareness of common conformal coating defects provides a useful lens for evaluating suppliers. For manufacturers, it reinforces the importance of discipline: when the process is right, conformal coating works beautifully; when it’s not, even the smallest slip can create significant problems.

At Active-PCB Solutions, we’ve built our conformal coating process to minimise these risks, combining skilled oversight with robust controls to ensure reliable protection for every assembly.

Ready to plan your next project? Contact Active-PCB today to discuss a coating solution that works for you.