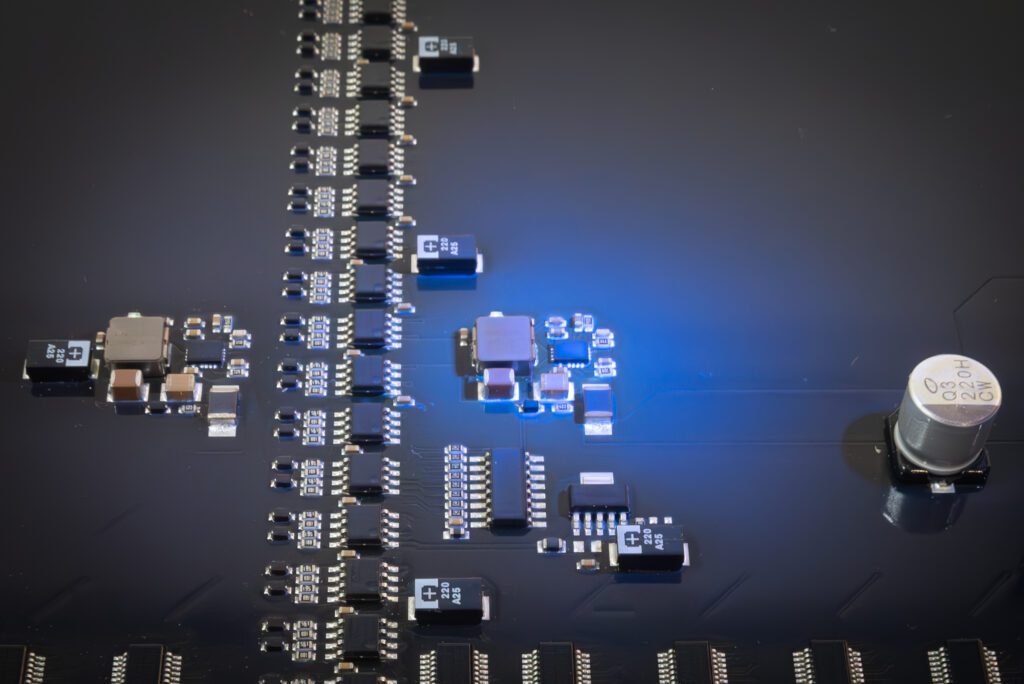

Conformal Coating

Active-PCB Solutions offers in-house conformal coating, allowing us to protect your assembled PCBs as an integral part of the manufacturing process before they are dispatched.

For electronics operating in challenging environments, conformal coating provides essential protection against contaminants and environmental stress. By carrying out coating in-house, we maintain full control over application, quality and traceability, while reducing lead times associated with subcontracting.

We provide a range of conformal coating services using proven application techniques, including spray coating and potting, selected to suit the specific requirements of each assembly.

Conformal coating helps protect against moisture and chemical exposure, reduces the effects of vibration, and minimises the risk of current leakage, improving long-term reliability and performance.

Originally developed for military and aerospace applications, conformal coating is now widely used across many industries. Our experience and controlled processes ensure that every coated assembly meets the highest quality standards and is delivered ready for use.

Our Conformal Coating Services | Active-PCB Solutions

At Active-PCB Solutions, we recognise the importance of safeguarding electronic systems that operate in harsh environments. Conformal coating provides essential protection against potential contaminants such as moisture, chemicals, dust, and more, and helps to ensure that your products perform reliably even under the most challenging conditions.

Our Capabilities

Our Capabilities

- Automated In-Line Coating Line – Rehm Protecto XP Selective Coater

- Precision selective application for both high-volume and high-mix builds

- Four head system – the first in the UK – applying up to four materials in a single process

- Fully programmable via ODB++/Gerber data

- Complete traceability and repeatability

- Advanced Curing Systems – Vanstrom VHB-250 In-Line Oven

- Multi-zone temperature control up to 200°C

- Vertical buffer equivalent to 40m oven length for compact efficiency

- Batch or in-line processing, up to 50 pallets simultaneously

- Manual Coating & Inspection

- UV inspection booths and semi-automated spray stations for complex assemblies or prototypes

- Wash Process

- Fully automated 4-stage wash process: cleaning, rinse, DI rinse, evaporative dry

- Ionic residue monitoring ensures boards are coating-ready

Materials We Use

- Nanocoating: Ultra-thin and lightweight, waterproof to IPX7/IPX8, flexible and environmentally friendly protection for sensitive components. Does not require time consuming masking making it a low cost option.

- Acrylic (1B31): Versatile, quick-drying protection with good moisture resistance and good dielectric properties. Can be re-worked.

- Urethane (1A33): Excellent chemical and mechanical resistance. Good moisture and humidity resistance.

- These coatings are applied in our in-house conformal coating facility.

- We are also able to provide Silicone and Parylene conformal coating via our trusted partners

What is Conformal Coating and What is it Used For?

Conformal coating is a thin, protective layer which is applied to electronic components to shield them from environmental factors that could compromise their functionality. Originally developed for military and aerospace applications, this technology is now a vital solution across industries – from automotive and medical to industrial and consumer electronics – where equipment is required to withstand tough conditions.

Conformal coating also offers several additional benefits:

- Moisture and Chemical Resistance: Protects electronics from moisture ingress and chemical contamination, extending their operational life.

- Vibration Dampening: Reduces the impact of vibration, minimising potential mechanical stress on sensitive components.

- Reduced Current Leakage: Provides a stable, insulated surface, helping prevent unwanted current leakage that could otherwise lead to malfunction.

Flexible Coating Solutions for Every Application

Through our network of trusted providers, Active-PCB Solutions arranges access to a variety of conformal coating techniques, allowing us to accommodate a broad range of product specifications and environmental requirements.

- Spray Coating: A versatile, efficient option for even coverage that provides effective protection against contaminants and mechanical stress.

- Potting: Potting encloses components fully for maximum protection in extreme conditions, ideal for applications needing robust, long-term stability.

Our team understand that every project’s needs are unique, and our experienced team will consult with you to determine the optimal coating method, materials, and specifications to meet your performance, durability, and environmental requirements.

Quality and Reliability You Can Trust

At Active-PCB Solutions, we are dedicated to ensuring that each component we deliver is protected to the highest standards. Our experience across sectors enables us to work with diverse coating materials and techniques, providing custom solutions that enhance product longevity and functionality. Our clients trust us to deliver not only robust electronics but also coatings that meet stringent quality requirements.

Partner with Active-PCB for Enhanced Product Protection

Whether you’re seeking enhanced durability for electronics in demanding applications or looking to extend the lifespan of your product, Active-PCB Solutions is here to help. Contact us today to discuss your conformal coating needs, and discover how we can support your project with tailored, high-quality protective solutions that keep your products performing at their best.