Ensuring Long-Term Reliability in Ball Grid Array (BGA) Assembly

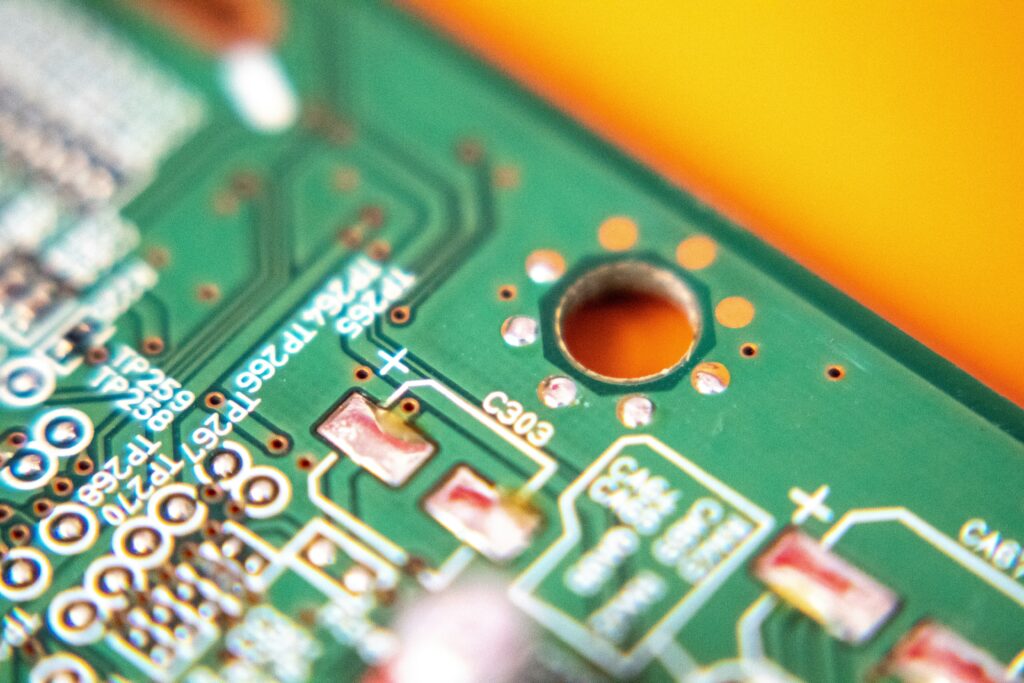

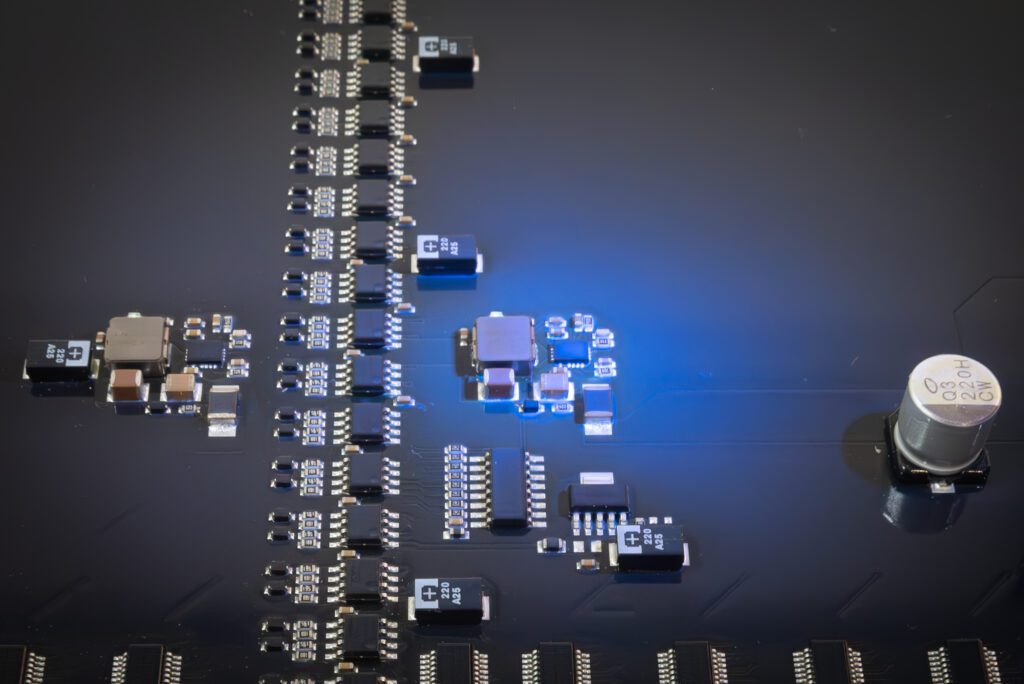

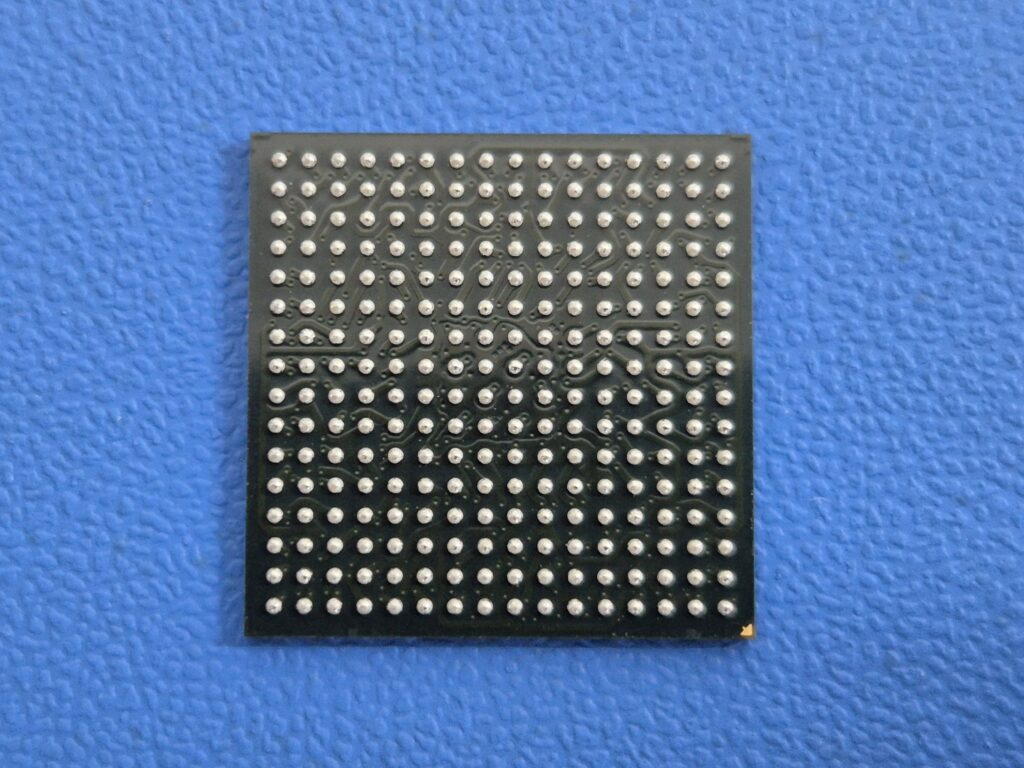

As electronics become more compact, powerful, and complex, Ball Grid Array (BGA) assembly has become an essential in modern PCB design. Their ability to support high pin counts and maintain signal integrity makes them ideal for advanced applications including aerospace, medical and industrial electronics. However, with these benefits comes one critical challenge: ensuring long-term reliability. […]

Ensuring Long-Term Reliability in Ball Grid Array (BGA) Assembly Read More »