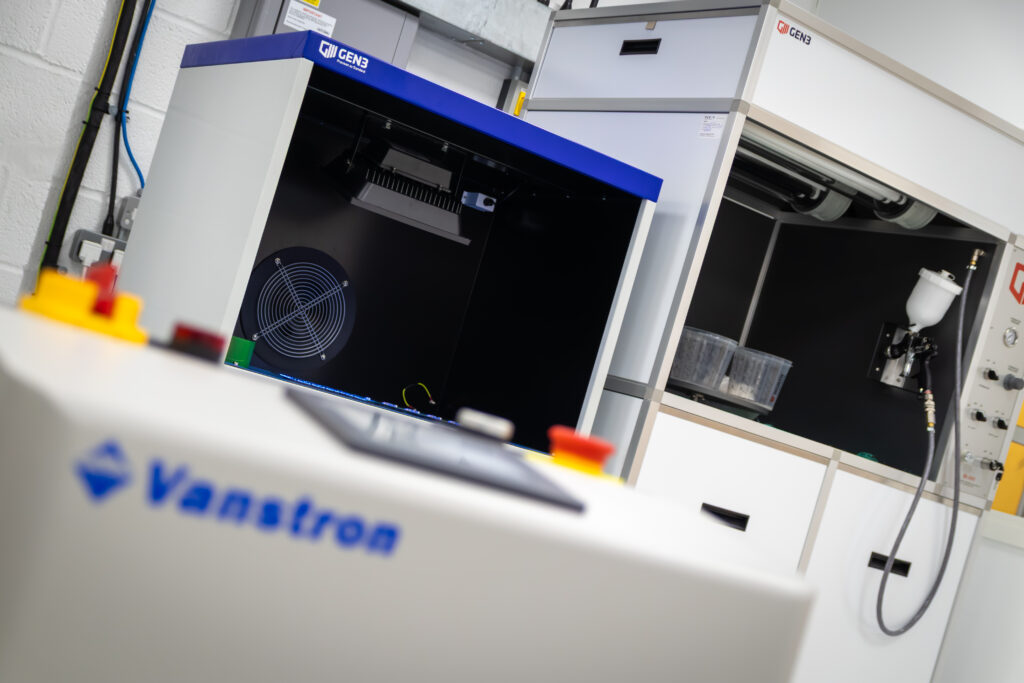

We are proud to announce that Active-PCB Solutions has recently invested in a fully integrated, in-house conformal coating facility. This strengthens our end-to-end manufacturing capability, giving our customers access to controlled, production-ready conformal coating for PCBs in the UK, without reliance on third-party subcontractors.

Our investment was a direct response to market needs. As electronics are increasingly deployed into harsher, more demanding environments, protecting assemblies after manufacture has become a critical part of the process rather than an optional extra. Moisture, chemicals, dust, vibration, temperature extremes and electrical leakage can all pose real risks to a PCB’s performance, longevity and safety – and conformal coating provides vital protection against these threats.

We are now able to deliver conformal coating as a fully integrated part of the manufacturing process, not as an outsourced afterthought. For our customers, that means better quality control, shorter lead times, improved traceability, and a single accountable partner from build through to final protection.

What is conformal coating And Why It matters

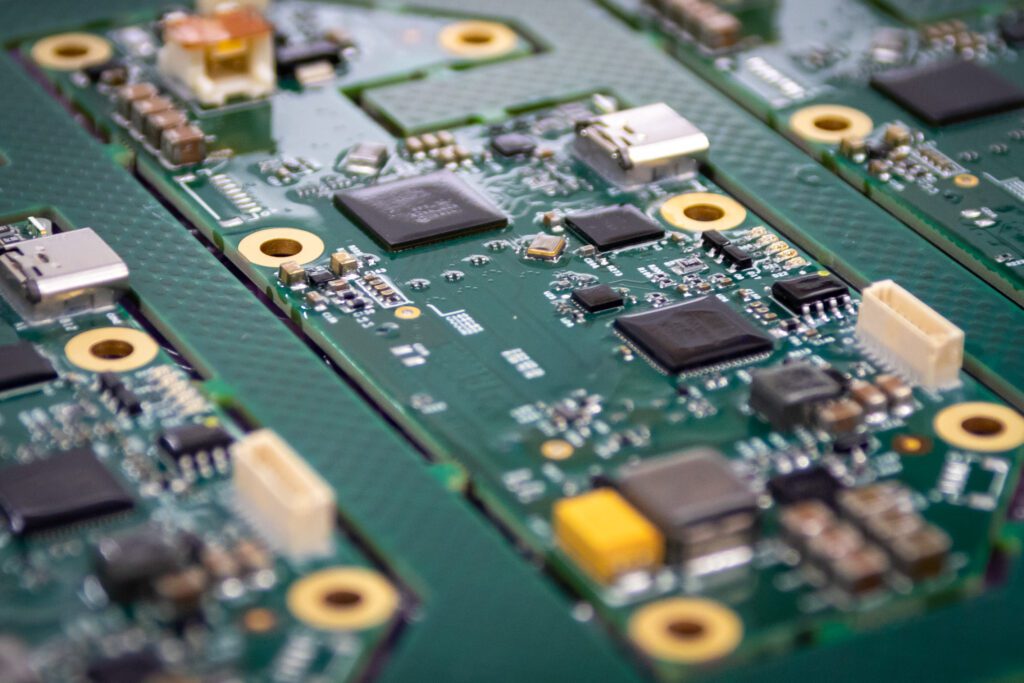

Conformal coating is a thin, protective polymer layer applied to assembled PCBs. It ‘conforms’ to the surface of components and circuitry, forming a barrier that helps protect electronics from environmental and operational damage.

Traditionally driven by aerospace and military requirements, conformal coating is now widely used across sectors including industrial electronics, medical devices, communications, automotive, motorsport and consumer products. As electronics become smaller, denser and more complex, the need for reliable protection increases.

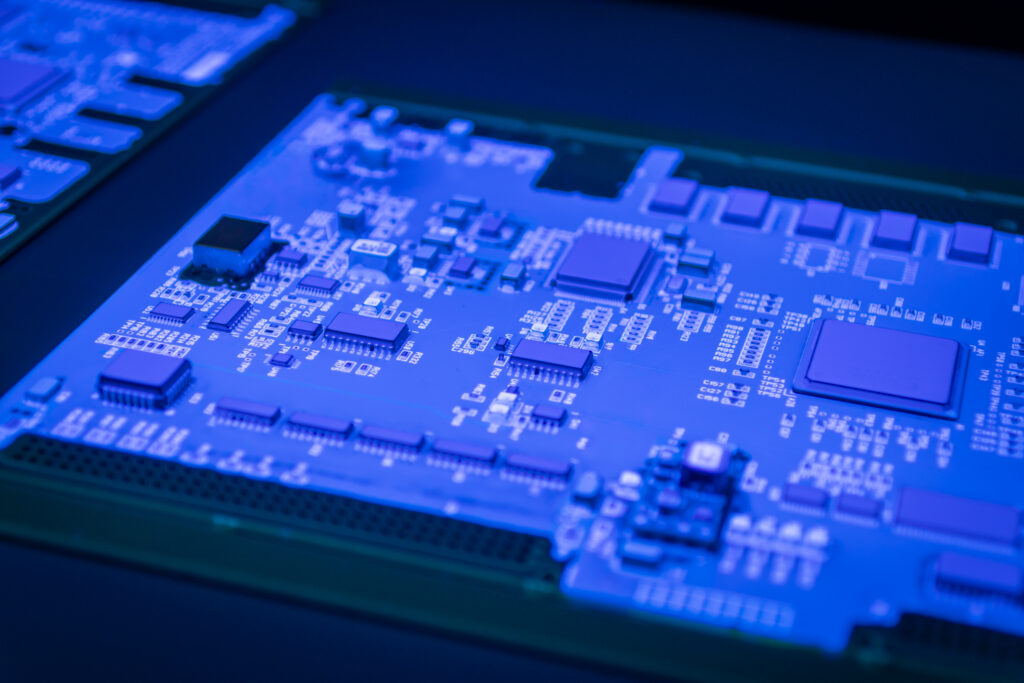

More importantly, modern product lifecycles demand consistency and repeatability. Coating must be applied accurately, predictably and cleanly, without introducing new risks through contamination, masking errors or inconsistent curing. That’s exactly what our new facility has been designed to deliver.

Multiple coating technologies, one controlled environment

Not all applications require the same type of protection, which is why our facility supports multiple coating technologies.

We now offer nanocoating, acrylic coating and urethane coating fully in-house, allowing us to tailor protection to each product’s environment, performance requirements and lifecycle needs.

Nanocoating provides ultra-thin, lightweight protection with excellent moisture, temperature and chemical resistance. It is particularly well suited to compact electronics where mechanical bulk is not required, and where fast, clean application without masking is beneficial. The PCB powering your mobile phone is very likely nanocoated, for example.

Acrylic coatings such as Humiseal 1B31 remain a widely used solution for general environmental protection. They offer fast drying times, good dielectric properties and easy reworkability, making them ideal for many commercial and industrial applications.

Urethane coatings such as Humiseal 1A33 provide higher chemical resistance and stronger mechanical protection for harsher operating environments, where durability and long-term stability are critical.

In addition, where specific applications require alternative technologies, we also support silicone and parylene coatings via trusted specialist partners, ensuring customers always receive the right protection for their product, not just the most convenient option.

Active PCB’s Conformal Coating Machinery

Our conformal coating capability is not a standalone machine, it is a fully integrated production system. At the heart of the facility is a Rehm Protecto XP selective coating machine, allowing highly accurate, programmable application using ODB++ and Gerber data, image capture and fully automated process control.

Selective coating significantly reduces the need for masking, which drastically reduces lead time and the chance of human error, improving repeatability and enabling both high-mix, low-volume production and scalable manufacturing. Up to four coating materials can be available simultaneously, eliminating downtime between changeovers and improving production efficiency.

This is supported by in-line and batch curing ovens, automated wash processes, UV inspection and rework stations, and controlled manual spray facilities. Every stage of the process has been designed around quality, traceability, cleanliness and consistency.

The result is a production-ready environment that supports real manufacturing demand.

What this means for Our customers

Bringing conformal coating fully in-house transforms how protection is delivered as part of the build process. Customers benefit from shorter lead times, improved quality control, reduced supply chain risk and full process accountability. There is no handover between suppliers, no loss of traceability, and no separation between assembly and protection.

It also allows coating to be engineered into the production process properly, rather than added at the end as a disconnected step. This improves reliability, reduces rework risk, and ensures consistency across batches and builds.

Most importantly, it allows Active-PCB to deliver true end-to-end manufacturing:

Prototype → PCBA → Testing → Conformal Coating → Box Build → System Integration

All under one roof, all UK-based, all quality-controlled.

Conformal Coating for PCBs UK delivered properly

This latest investment represents a significant step forward in how we support customers building reliable electronics for demanding environments. It strengthens our capability, reduces supply chain risk, and gives customers direct access to professional, production-grade Conformal Coating for PCBs in the UK as part of a fully integrated manufacturing service.

Whether you’re developing new products, scaling production, or looking to improve reliability in harsh operating conditions, our in-house coating capability allows us to protect your electronics properly.