Nanocoating is a type of conformal coating; a process which plays a critical role in protecting electronic assemblies from environmental damage. As electronics are increasingly used in harsher environments, are becoming more compact and used in more demanding applications, conformal coating – and choosing the right type of coating – is more important than ever.

Active-PCB are now able to provide nanocoating in our in-house conformal coating facility. But how does nanocoating compare to more traditional conformal coatings such as acrylics and urethanes, and when is it the right choice?

What Is Nanocoating?

Nanocoating is a protective layer applied to the PCB which is ultra-thin; often measured in nanometres rather than microns. Unlike traditional conformal coatings that form a visible film over the PCB, nanocoatings bond at a molecular level, creating a highly uniform barrier across components, solder joints and surfaces.

Despite its minimal thickness, nanocoating provides effective protection against moisture, condensation, dust and many contaminants, without adding bulk or significantly altering the physical profile of the assembly.

Key Benefits of Nanocoating

Nanocoating provides a highly effective form of protection while adding minimal weight or thickness to a PCBA. Its ultra-thin application creates a uniform barrier that shields electronics without impacting functionality or design.

Key benefits include:

- Extremely lightweight, making it ideal for compact or weight-sensitive applications

- High levels of waterproof protection, achieving performance comparable to IPX7 and IPX8 ratings when correctly applied

- Excellent resistance to elevated temperatures, maintaining performance in demanding operating environments

- Strong chemical resistance, helping protect against oils, fuels, cleaning agents and other contaminants

- No masking required, reducing preparation time and eliminating the risk of human error or incomplete coverage

- No post-coating cleaning needed, simplifying the process and reducing handling

- Cost-effective protection, particularly for high-density or complex assemblies

- Environmentally friendly formulations, with reduced material usage and waste

When Nanocoating Is the Right Choice

Nanocoating as a method of conformal coating is particularly well suited to:

- Compact or high-density PCB assemblies

- Products which will be exposed to humidity, condensation or light contamination

- Applications where weight and size are critical

- Assemblies with connectors or components that must remain functional without masking

It is commonly used in consumer electronics such as mobile phones, industrial controls, communications equipment and other applications where environmental protection is required but space is at a premium.

When a Different Coating May Be Better

While nanocoating offers many advantages, it is not the right solution for every application.

For assemblies likely to be exposed to harsh chemicals, fuels or solvents, thicker traditional coatings such as urethanes or silicones may provide more robust resistance.

In applications involving extreme temperatures or significant mechanical stress, silicone coatings can offer superior flexibility and thermal stability.

For the highest levels of protection, particularly in aerospace or medical applications, parylene coatings may be required. Parylene provides exceptional barrier performance but involves a specialist vapour deposition process and is typically outsourced.

Acrylic coatings remain a popular choice where cost-effectiveness, ease of rework and general environmental protection are key requirements.

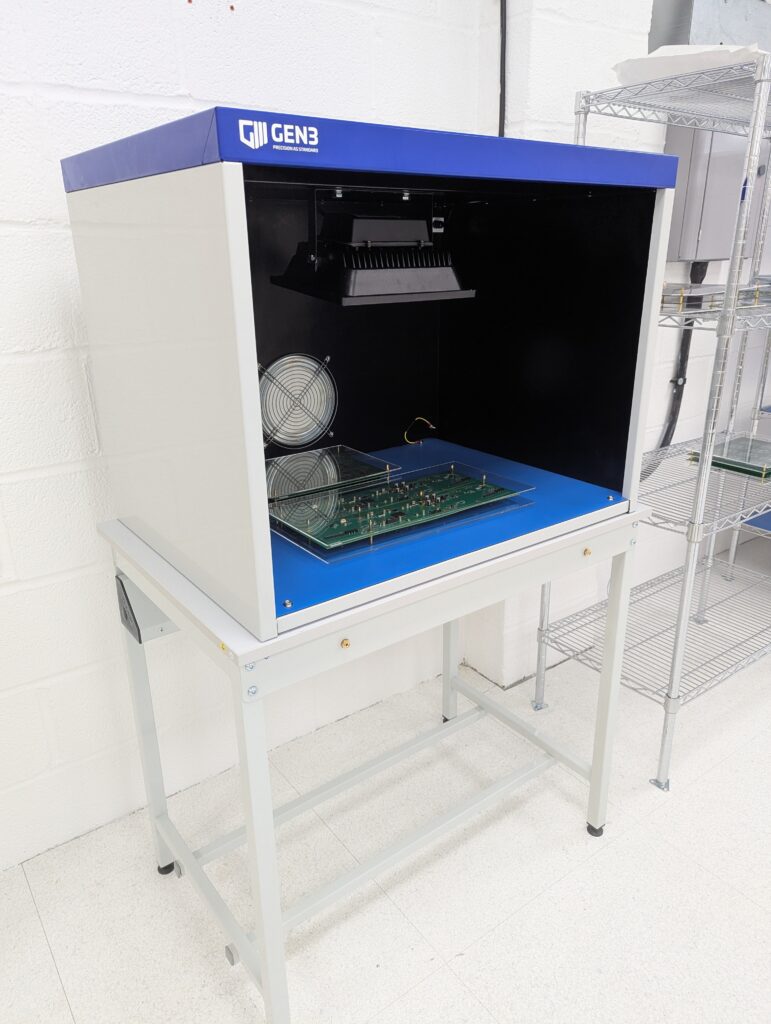

Active-PCB’s In-House Conformal Coating Capability

At Active-PCB Solutions, we offer nanocoating, acrylic and urethane conformal coating in house, allowing coating to be fully integrated into the PCB assembly process. Our Rehm Protecto XP Selective Conformal Coating Machine has four heads which allow up to four materials at any one time, meaning no down time between switching coating types.

This means we can provide greater control, reduced lead times and improved consistency compared to subcontracted coating.

For applications requiring alternative solutions, including silicone or parylene coatings, we work closely with trusted specialist contractors to ensure the correct coating is applied without compromising quality or traceability.

By offering multiple coating options, we can help customers select the most appropriate solution based on environment, performance requirements, rework needs and cost.

Choosing the Right Conformal Coating

Selecting the right conformal coating is about balancing protection, performance and practicality. Nanocoating offers an excellent solution where space is limited and uniform protection is required, while traditional coatings continue to play a vital role in harsher environments.

Our team works closely with customers to understand operating conditions and product requirements, ensuring the chosen coating supports long-term reliability.

If you would like to discuss nanocoating or any of our conformal coating services, please get in touch to explore the best option for your application.