Adding Agility to Electronics Manufacturing

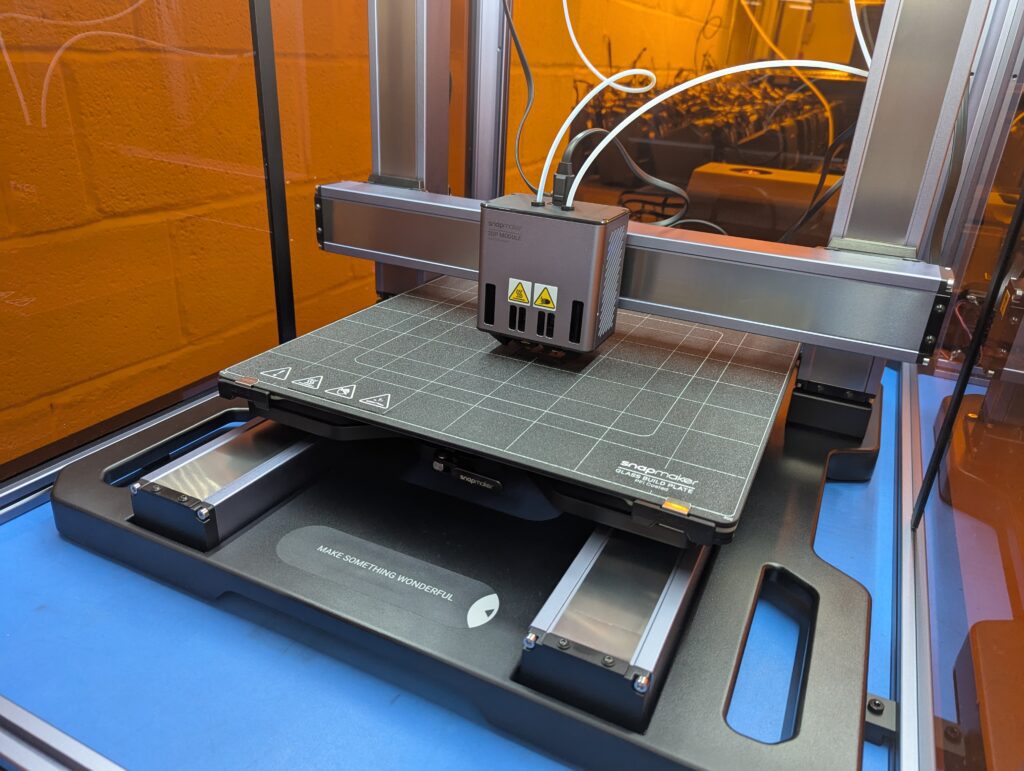

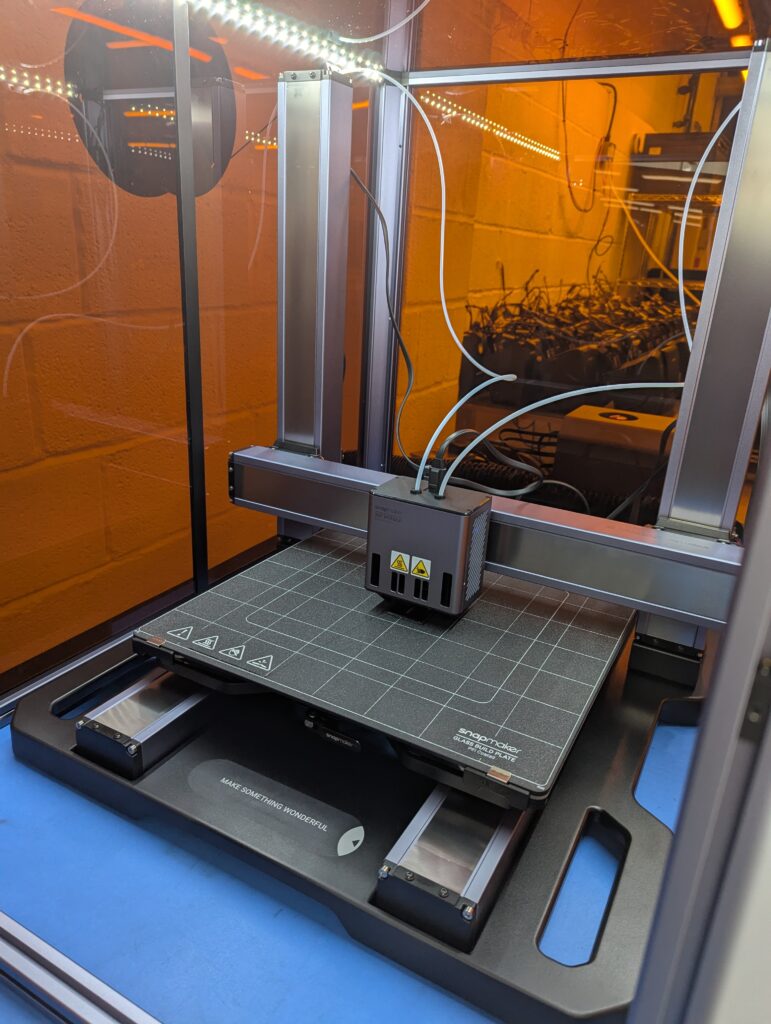

At Active-PCB Solutions, innovation is part of how we work. Our latest investment, the Snapmaker Artisan 3-in-1 system, combines 3D printing, CNC milling, and laser engraving in a single, highly capable and surprisingly compact platform.

We’re excited about this shiny, new bit of equipment – it’s a way to accelerate problem-solving and boost flexibility across our PCB assembly operations.

Why a 3-in-1 System?

Traditional tooling and fixture fabrication can be slow and expensive, especially when every PCB design has unique requirements. The Snapmaker Artisan 3-in-1 system gives our engineers the ability to:

- 3D print precision tooling, jigs, and conformal coating masks

- CNC machine durable fixtures or housings from solid materials

- Laser engrave labels, markings, and component identifiers for rapid traceability

All of this can happen on-site, within hours, instead of waiting days for external machining or outsourced fabrication.

Practical Benefits in PCB Assembly

Conformal Coating Masking

Certain components need protection during conformal coating. With the Snapmaker Artisan’s 3D printing and CNC modes, we can create custom-fit shields and masks that precisely cover sensitive parts, improving finish quality and reducing manual masking time.

Tooling & Assembly Fixtures

Quick-turn fixtures, spacers, or alignment guides can be printed or machined to exact specifications. This helps our technicians handle boards more safely and repeatably during assembly and test.

Rapid Prototyping

When working with new designs or evaluating a mechanical interface, being able to print or machine a model on demand allows faster validation before committing to full tooling.

Laser Marking & Identification

Using the laser module, it is possible to mark tooling or components with part IDs, revision codes, or QR data for better traceability and organisation.

Why This Matters for Our Customers

Speed and precision go hand in hand in electronics manufacturing.

By integrating the Snapmaker Artisan 3-in-1 system, we can:

- Deliver faster project turnaround

- Maintain consistent quality through custom tooling

- Reduce dependency on external suppliers

- Support continuous process improvement directly on the shop floor

It’s a small addition that we hope will make a big difference in how we support customers, especially in quick-turn and high-mix production environments.

Looking Ahead

As manufacturing continues to evolve, tools like the Snapmaker Artisan 3-in-1 3D printer exemplify the future: versatile, digital, and responsive.

At Active-PCB Solutions, we’re proud to adopt technologies that empower our teams to innovate, ensuring that every board we build benefits from precision, creativity, and efficiency.

Curious how we can can help your next project? Get in touch with the team at www.active-pcb.com