At Active-PCB Solutions, continuous improvement is not just a buzzword – it is a practical commitment that shapes how we invest, how we train our people, and how we support our customers.

Over the past year, we have made significant investments across our manufacturing operation, with a clear focus on strengthening capability, improving efficiency, and supporting increasingly complex PCB assembly requirements.

These investments have been made deliberately and strategically. They are not about short-term gains or headline equipment purchases. They are about building a robust, future-ready manufacturing environment that delivers consistent quality, faster turnaround, and greater flexibility for our customers.

Strengthening Inspection, Traceability and Control

A key area of focus has been inspection and process control. We have invested in a Quins First Article Inspection system, allowing faster, more accurate verification of first-off assemblies. This improves confidence at the earliest stage of a build, reduces the risk of repeat defects, and supports smoother transitions from prototype to production.

To strengthen material control and inventory accuracy, we have added a Seamark X-ray component counter. This enhances component counting and verification, helping ensure material accuracy while improving efficiency in kitting and stock management.

We have also introduced laser marking equipment, enabling permanent, high-quality marking directly onto assemblies. This supports traceability, product identification, and compliance requirements, particularly for customers operating in regulated or high-reliability sectors.

Improving Line Flow and Manufacturing Efficiency

Alongside inspection and traceability, we have invested in the flow and efficiency of our SMT operation. A new stacker and buffer system has been installed to improve line balancing, reduce manual handling, and increase flexibility across builds. This allows us to manage varying batch sizes more effectively and supports faster, more consistent throughput without compromising quality.

These kinds of investments are often less visible than headline machinery, but they play a critical role in delivering reliable, repeatable manufacturing performance day in, day out.

Expanding In-House Capability with Conformal Coating

One of the most significant developments this year has been the creation of a dedicated in-house conformal coating room. This controlled environment allows us to deliver conformal coating as a fully integrated part of our manufacturing process, rather than relying on external suppliers.

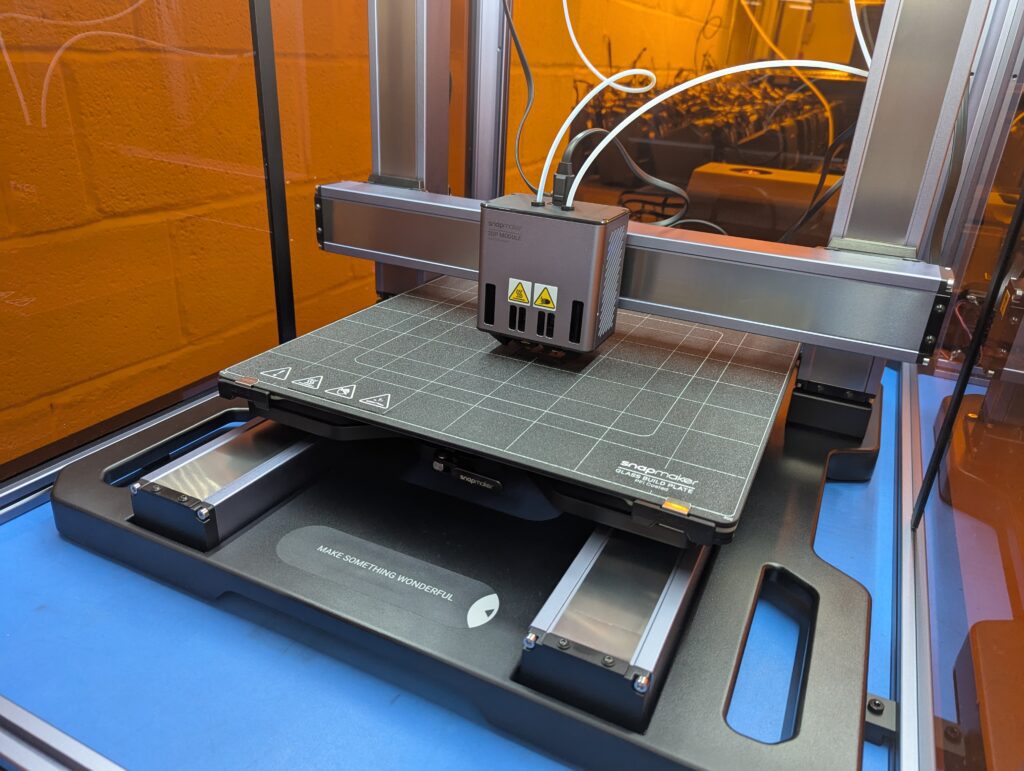

By bringing conformal coating in-house, we have improved control, reduced lead times, and increased flexibility for customers who require environmental protection for their assemblies. This capability is further supported by our Snapmaker Artisan 3-in-1 3D printer, which is used to produce bespoke tooling, fixtures and masking solutions.

This is particularly valuable for selective coating and complex assemblies where precision is critical.

Investment in People and Training

It is often overlooked, but technology alone does not deliver quality. Every equipment investment is matched by ongoing investment in training and skills development. Our teams receive regular training to ensure they can fully utilise new systems, maintain the high standards we are proud of, and adapt to evolving customer requirements.

This focus on people at Active-PCB ensures that new capability translates into real-world benefits. Better consistency, improved problem-solving, and greater confidence across the production floor.

Built for the Year Ahead

Together, these investments strengthen Active-PCB’s ability to support fast-turn PCB assembly, complex builds, and integrated services from prototype through to production. They reflect our commitment to doing things properly, investing ahead of demand, and continuously improving how we operate.

If you are planning new builds, facing tighter timelines, or looking for a manufacturing partner with the capability to support complex PCB assemblies, now is a good time to talk. Get in touch with the Active-PCB team to discuss how these investments can support your next project.

To learn more about our capabilities or to discuss your next project, contact our team: 0118 932 1122, sales@active-pcb.com.