PCB Assembly

One of the UK’s leading contract manufacturers

While an exemplary service and excellent customer communication is at the heart of the business, assembled circuit boards are what Active-PCB makes.

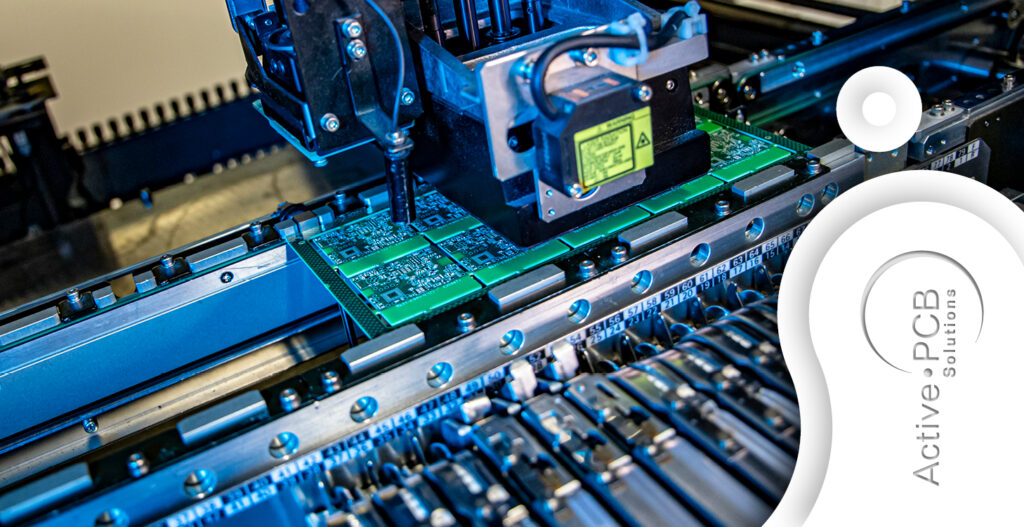

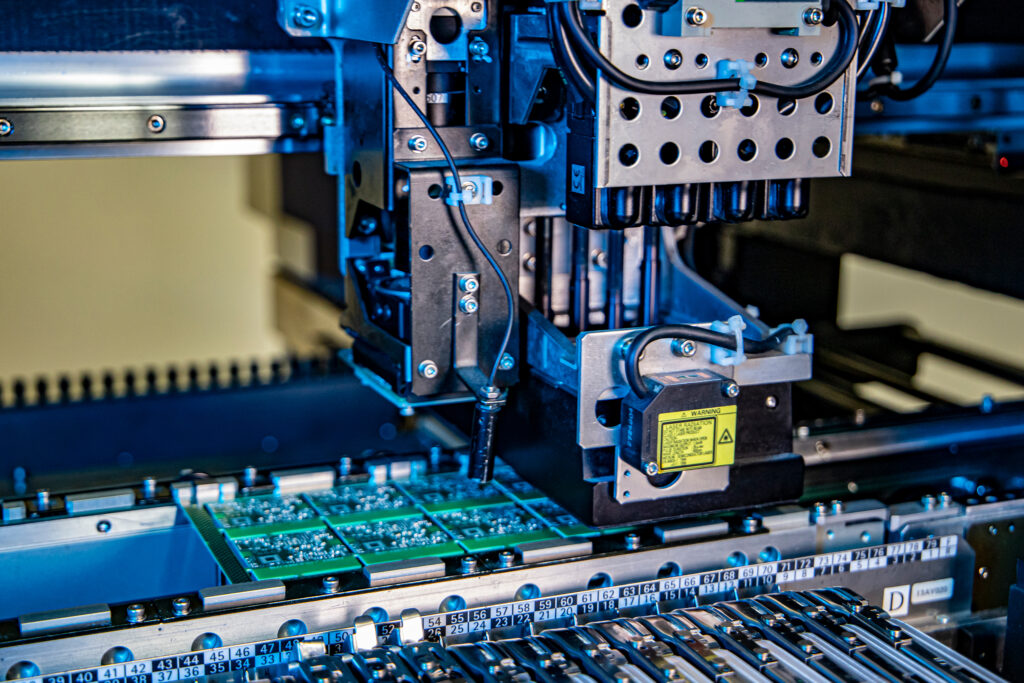

Assembling a printed circuit board is an intricate, precise process that requires high levels of focus and concentration from all parties. As well as a strong attention to detail, this demanding work requires the finest tools available. That’s why the company, as one of the UK’s leading contract manufacturers, has invested heavily in equipment to provide the tools needed to perform and deliver.

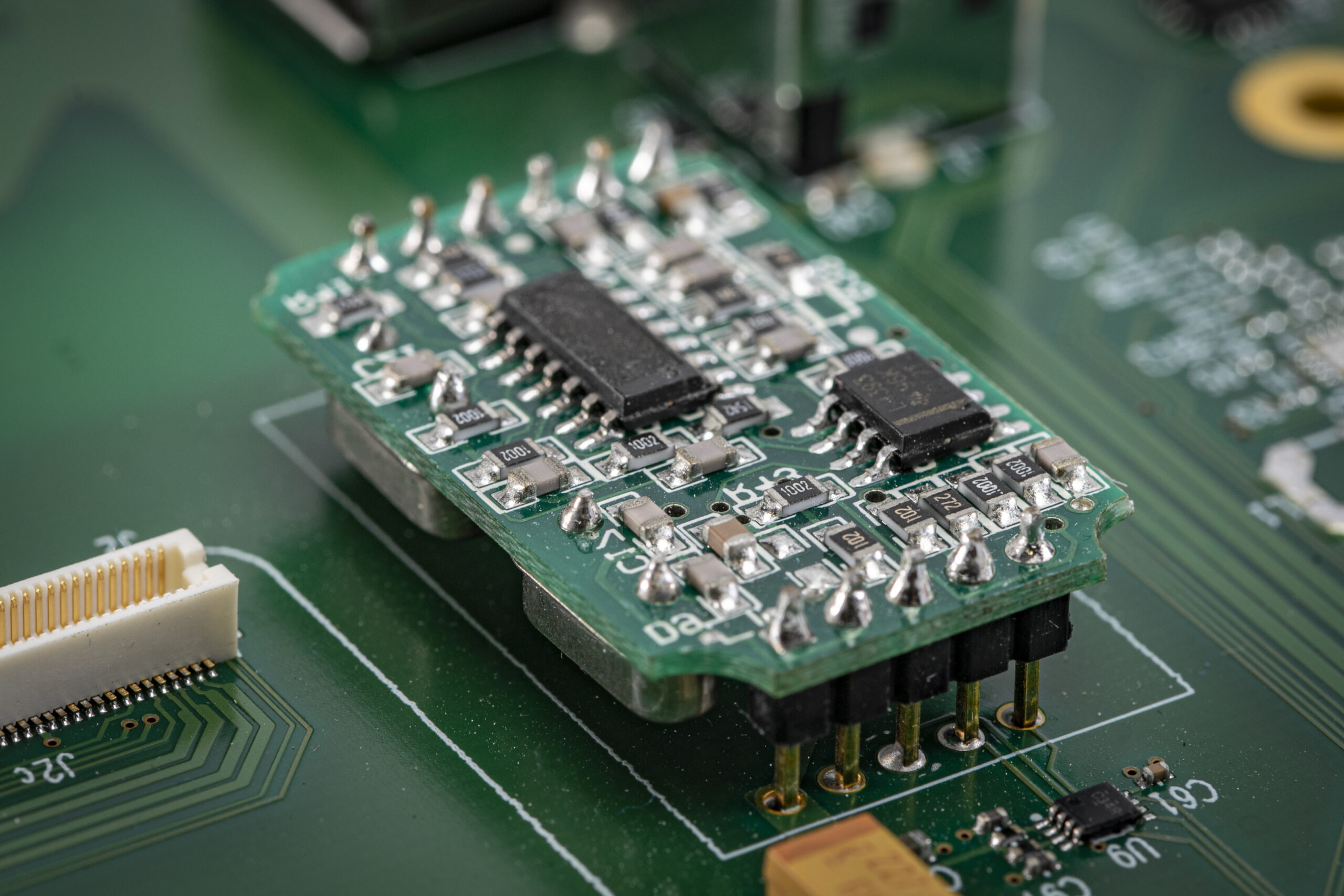

The company’s capability in Printed Circuit Board (PCB) assembly stretches from complex surface mount and conventional through-hole to electro-mechanical assembly and full product build. In the process, Active-PCB undertakes component procurement and a rigorous test & inspection regime, while attention to detail is second-to-none.

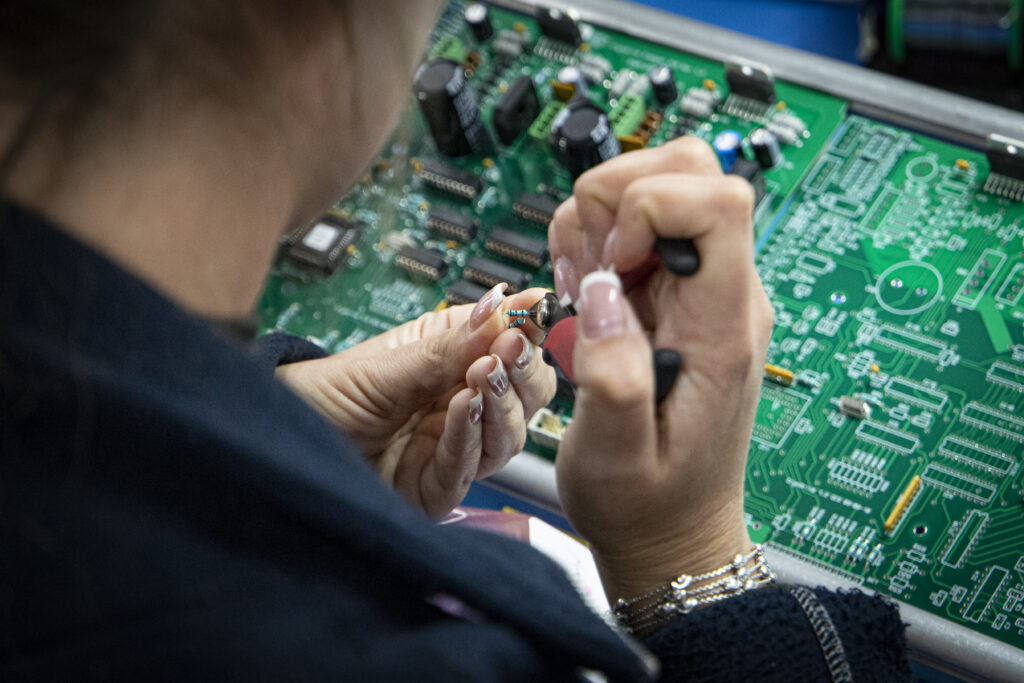

Conventional Through-Hole Assembly

Browse through Active-PCB’s services to find out more about the company’s skills, and how through-hole technology still has its place and is common in power assemblies.

Active-PCB offers several methods for conventional assembly including flow soldering, selective soldering and precision hand soldering.

Automated insertion and other specialist equipment maintain productivity levels while meeting customers’ specific through-hole manufacturing and quality requirements.

Surface Mount Assembly (SMT)

PCB assembly does not necessarily mean that the component leads need to pass through the board. They can instead be soldered onto the board, and this is now a very common method of PCB assembly.

The SMT manufacturing area deploys Juki placement machines, DEK screen printers and BTU reflow ovens to offer a full range of electronics assembly options. Components down to 01005 and up to QFP and BGA are handled with ease. Large batch volume capability covers complex technologies like flip-chip, package-on-package (PoP), Micro BGAs, QFNs and exacting Ultra-Fine Pitch work.

Contact us so we can better understand you

Every customer has their own needs, their own standards to adhere to and their own projects with unique specifications. Active-PCB is a partner in finding the right solution first time. Ask us a question, request information or enquire whichever way best suits you.